Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) is a powder bed AM technology that produces highly accurate and durable parts capable of being used directly in end-use, low-volume production. SLS is a newer AM process that is often thought of as a cousin to the popular metal AM technology. Both processes work by utilizing a laser to precisely fuse a bed of powder to construct a part from a 3D CAD file. SLS specializes in nylon or polyamide powder particles to create parts, while DMLS uses metal particles, and is extremely common for prototyping and low volume production.

Functional Principle

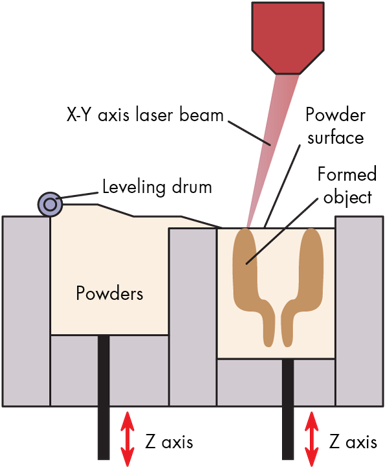

SLS is an additive manufacturing layer technology involving the use of a high power laser, which fuses small particles of nylon powder into a three-dimensional shape. The laser selectively fuses powdered material by scanning cross-sections generated from a 3-D digital description of the part (for example from a CAD file or scan data) on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness, and a new layer of material is applied on top. This process is repeated until the part is finished.

Advantages / Disadvantages SLS

Selective Laser Sintering can be used to make parts using a variety of materials, including plastic, metal, ceramic, or glass powder, making it a popular machining process. Since SLS doesn’t require a support structure like most other AM technologies, parts can be made in greater quantities, but with less labor and material expense. Additionally, because the support structure doesn’t need to be removed, there is less risk of damage to the complex internal geometries additive manufacturing is capable of producing.

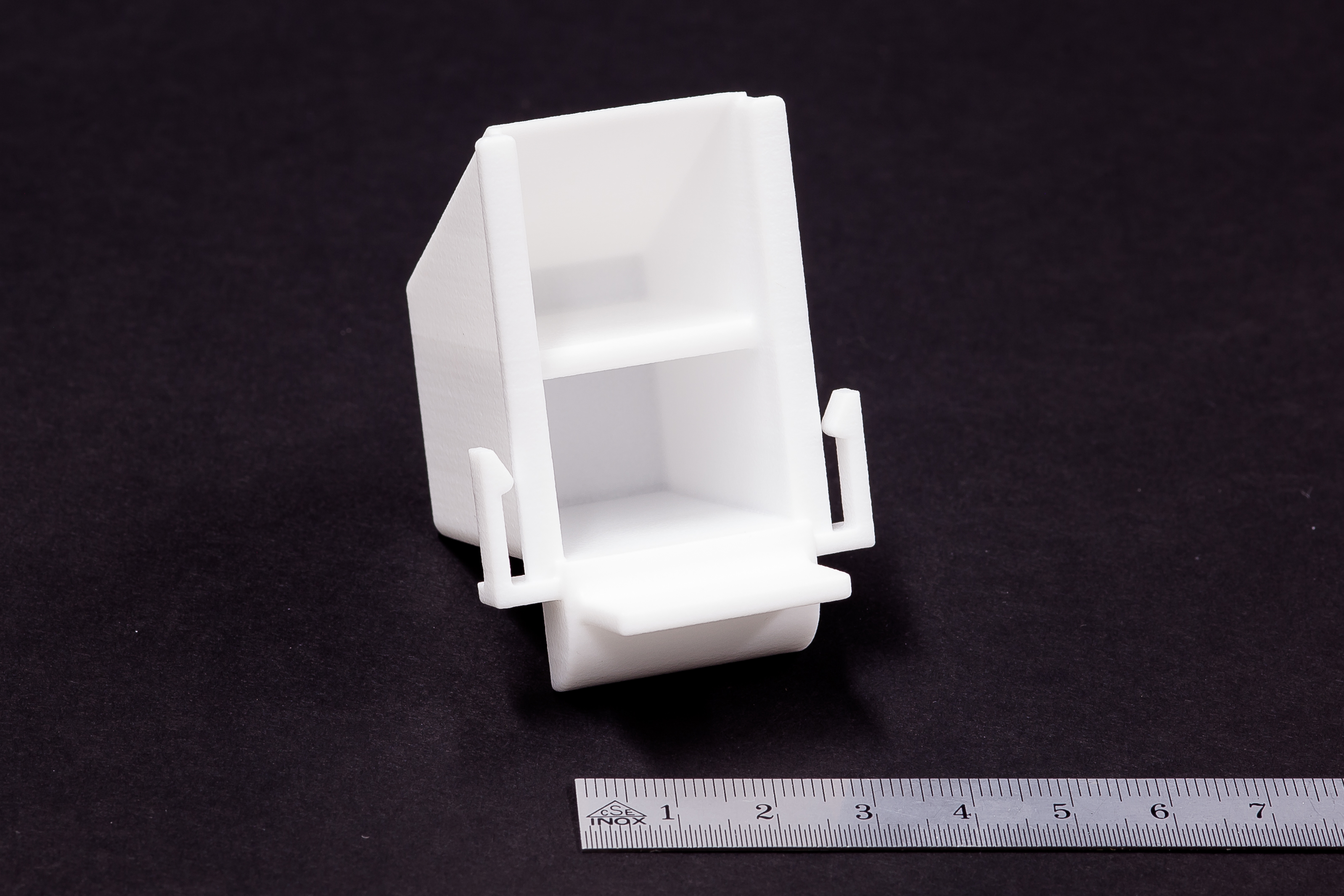

SLS can be useful for both rapid prototyping or small numbers of functional end-use parts. Nylon, especially, is a durable material with great impact strength, medium flexibility, and high resistance to environmental factors. This combination of complexity, design flexibility, material diversity, rapid turnaround, and overall durability makes SLS an increasingly popular choice in many industries.

A disadvantage is however that laser sintering parts do not have exactly the same properties as their injection molded counterparts. Especially in regards to surface finish, if no post treated processes are applied.

Ideal applications for SLS

- Prototypes with mechanical properties to rival those of injection-molded parts.

- Series of small components as a cost-effective alternative to injection molding.

- Personalized manufacturing, the economical production of unique, complex, designs built as one-off products or in small batches.

- Unavailable polymer spare parts which have originally been injection molded.

- Lightweight designs using complex lattice structures.

- Steam sterilizable and bio-compatible parts.

Which material is available

PA2200 is a fine-powder on the basis of polyamide 12 material which offers excellent strength and stiffness, good chemical resistance with excellent long-term consistency in material properties (view spec sheet).

More materials are available in cooperation with external manufacturers.